You step into a world where engineering becomes art: F1 engines blend brutal power with surgical precision to deliver lap-after-lap excellence. You’ll learn how hybrid power units, bespoke materials, and razor‑sharp tolerances create a machine that feels luxurious because it converts extreme performance into predictable, controllable speed.

This article breaks down how that luxury appears — from the high‑revving thermodynamics and electronic integration to aerodynamic demands and luxury finishes — and shows why innovations on the track ripple into high‑end road cars. Expect clear explanations of the engineering choices, the practical challenges teams face, and what the next generation of F1 engines means for performance and refinement.

Understanding F1 Engine Luxury

F1 engine luxury means combining peak on-track performance with elite engineering, advanced materials, and exacting manufacturing tolerances. It covers how power units achieve extreme power density, rapid transient response, and integrated hybrid systems while remaining light and reliable.

Definition of F1 Engine Luxury

You should view F1 engine luxury as a package: a compact internal combustion engine (ICE) paired with high-power hybrid systems and bespoke ancillaries. Modern power units are 1.6‑liter V6 turbo hybrids that produce peak thermal-plus-electric power well above 900 PS in race trim, with energy recovery systems (ERS) that deliver instant bursts of electric torque.

Luxury also means components machined to micrometer tolerances, bespoke turbochargers, and exotic alloys for pistons, rods, and crankshafts. You get silicon carbide in inverter electronics, carbon fiber housings for some subsystems, and calibration maps tuned for milliseconds of throttle change. Every element trades cost for measurable performance gains.

Significance for Motorsport Innovation

You rely on F1 engine luxury as a testbed that accelerates road‑car technology. Energy recovery and hybrid control strategies developed in F1 migrate to production vehicles, improving fuel economy and transient response in high‑performance and mainstream cars alike.

Teams push materials science, cooling architectures, and software-managed combustion strategies. That pressure produces innovations in turbocharger efficiency, battery power density, and lightweight fabrication. You benefit when manufacturers scale those advances to consumer vehicles, safety systems, and manufacturing techniques.

Distinctive Characteristics Compared to Other Engines

Compared with road engines or other racing series, F1 units prioritize power density, transient response, and minimal mass. You see power-per-liter figures far exceeding production engines, and ERS adds immediate torque not typical in conventional ICEs.

Maintenance and lifecycle differ too: F1 engines require overhaul after limited hours and use telemetry for real‑time tuning. Packaging is far more compact; cooling is optimized for peak lap temperatures rather than sustained cruising. Noise, emissions, and cost constraints are managed differently, so you encounter technologies in F1 that wouldn’t be practical for mass-market use without adaptation.

- Key technical contrasts:

- Power density: very high

- Hybrid integration: ERS with MGU‑K and MGU‑H

- Materials: aerospace-grade alloys and coatings

- Service model: frequent rebuilds and telemetry-driven adjustments

Extreme Performance in Formula 1 Engines

You will read how modern F1 power units deliver massive, instantaneous power while staying light, durable, and fuel-efficient. Expect specific figures, materials, and systems that enable race-winning acceleration and top speed.

Power Output and Acceleration

F1 power units produce roughly 900–1,100 horsepower at peak race conditions when combining the internal combustion engine (ICE) and electric boost from the hybrid system. The 1.6-liter turbocharged V6 ICE typically delivers about 600–700 hp, while the Energy Recovery System (ERS) contributes around 160 hp for short bursts. You get up to 120 kW (≈160 hp) of electric power available for approximately 33 seconds per lap under current rules.

Torque delivery is immediate thanks to turbocharging and electric torque fill, which reduces turbo lag and smooths acceleration out of slow corners. Gear shifts occur in milliseconds through seamless semi-automatic transmissions, keeping the engine in its narrow optimal rpm band near 15,000 rpm. Those factors let cars accelerate from 0–100 km/h in about 2.5 seconds on a race setup.

Key performance controls you interact with during a race include multiple ERS deployment modes, fuel mapping, and brake regeneration settings. Teams tune these to balance lap time, battery state-of-charge, and engine reliability.

Cutting-Edge Materials and Lightweight Design

You encounter extensive use of titanium, Inconel, carbon fiber, and ceramic composites across the engine and ancillaries. Cylinder heads and valve gear often use high-strength alloys to withstand temperatures exceeding 1,000°C in localized areas. Turbine housings use nickel-based superalloys (Inconel) to survive extreme exhaust heat and high rotational speeds.

The crankshaft, connecting rods, and small components are optimized for minimum mass while meeting fatigue limits; many parts undergo proprietary heat treatments and surface coatings. The engine block and surrounding structures integrate carbon fiber mounts and magnesium alloy housings to reduce weight. Every 100 grams saved improves lap time, so teams iterate designs constantly.

You also face strict component life and homologation rules, so materials choices balance weight with durability and repeatability across race stints and season schedules.

Speed and Efficiency Optimization

You depend on thermal efficiency gains from turbocharging, high-pressure direct injection, and hybrid recovery to maximize usable energy from each kilogram of fuel. Current F1 units exceed 50% thermal efficiency—far above typical road cars—by recovering waste heat through the MGU-H and kinetic energy via the MGU-K. The MGU-H converts exhaust heat into electrical energy to spin the turbo or charge the battery, reducing fuel consumption while maintaining boost.

Aerothermal packaging matters: you must place radiators, intercoolers, and wastegate ducts to keep temperatures stable without creating drag. Software manages real-time energy deployment, switching between aggressive ERS modes for qualifying and conservative modes for race fuel economy and component preservation. Those systems let you extract peak lap speed and sustain competitive race pace with limited fuel allowances.

Precision Engineering Techniques

You will find processes that shape every cubic millimeter of an F1 engine, tight tolerances measured in microns, and bespoke parts engineered for peak power and reliability. These elements work together to deliver optimal combustion, minimal friction, and predictable performance under race conditions.

Advanced Manufacturing Processes

You rely on multi-axis CNC machining to create complex geometries like combustion chambers, turbo housings, and crankshafts with repeatable precision. Five-axis milling and electrical discharge machining (EDM) produce undercuts and internal shapes that traditional tools cannot reach, keeping weight low while preserving strength.

Additive manufacturing (metal 3D printing) lets you consolidate parts—reducing welds and fasteners—and create internal cooling channels or topology-optimized structures. Surface finishing methods such as superfinishing and shot peening improve fatigue life and reduce friction on bearing journals and valve stems. Each step uses in-process metrology to verify dimensions immediately, so you catch deviations before they propagate.

Microscopic Tolerances and Accuracy

You work to tolerances often in the single-digit micron range for components like piston-to-cylinder clearance and bearing oil film thickness. Those tolerances control heat transfer, oil pressure behavior, and sealing under 15,000–20,000 rpm, so small deviations affect power and longevity.

Non-contact optical profilers, coordinate measuring machines (CMMs), and laser scanners record form, roundness, and surface roughness to nanometer or sub-micron resolution. Statistical process control (SPC) monitors runs, and components failing drift limits trigger rework or scrap. Calibration routines reference gauge blocks and interferometry to maintain measurement traceability across production.

Custom Components for Maximum Performance

You get bespoke parts tailored to each track and engine map: tailored cam profiles, bespoke turbocharger turbine wheels, and custom exhaust geometries to tune backpressure and scavenging. Materials selection—titanium for connecting rods, Inconel for exhaust systems, forged aluminum alloys for pistons—balances mass, thermal stability, and fatigue resistance.

Every component undergoes validation: high-speed dyno maps, thermal cycling, and endurance runs replicate race stresses. Fasteners, coatings (dry-film lubricants, thermal barrier coatings), and lightweight bearings receive the same bespoke attention. When you run the engine, you use parts that have been designed, manufactured, and inspected to deliver the exact mechanical behavior you expect on race day.

Integration of Technology and Electronics

You’ll see precise coordination between chemical and electrical power, milliseconds-fast electronic control, and continuous streams of sensor data guiding every decision on car setup and strategy. These systems work together to deliver peak lap performance while respecting rules and reliability limits.

Hybrid Power Units and Energy Recovery

You rely on the power unit’s internal combustion engine (ICE) plus two electric systems: the MGU-K (kinetic) and MGU-H (heat). The MGU-K captures braking energy and redeploys up to regulated power levels to the drivetrain. The MGU-H harvests turbocharger heat, stabilizes spool-up, and can send energy directly to the MGU-K or recharge the battery.

Energy flow follows strict FIA rules: you have limited energy deployment per lap and battery capacity constraints. Teams map when to harvest and deploy in corners, straights, and during overtakes to maximize lap time while managing thermal and electrical limits. Battery chemistry, cooling, and power electronics design become critical for consistent performance across a race distance.

Electronic Control Systems

Your engine control unit (ECU) is the command center, running real-time control loops for fuel injection, ignition timing, turbo boost, and hybrid management. The homologated FIA ECU enforces software standards, but teams tune parameters within allowed windows to extract responsiveness and drivability.

Drive-by-wire systems govern throttle and differential behavior, and traction and torque distribution are adjusted by milliseconds to maintain grip. Safety features like engine protection maps and thermal cutbacks are automatic; they prevent component damage but can change car behavior under stress. You’ll find rugged, automotive-grade processors with redundancy to ensure reliability in high-vibration, high-temperature conditions.

Data Monitoring and Telemetry

You ingest thousands of sensor channels per second: temperatures, pressures, wheel speeds, g-forces, and electrical states. Onboard logging stores high-rate data, while compressed telemetry packets transmit selected channels to the pit via high-bandwidth radio links.

Engineers in the garage analyze live telemetry to adjust strategy, engine maps, and pit timing. You use visual dashboards and automated alerts to flag anomalies like rising oil temperature or battery imbalance. Post-session, detailed forensic analysis drives component choices, cooling upgrades, and calibration changes for future races.

Role of Aerodynamics in Engine Performance

Aerodynamics shapes how your engine breathes, how it sheds heat, and how effectively that power reaches the track. Small changes to airflow paths and pressure distribution can alter intake efficiency, cooling capacity, and tire grip in measurable ways.

Synergy Between Engine and Chassis Design

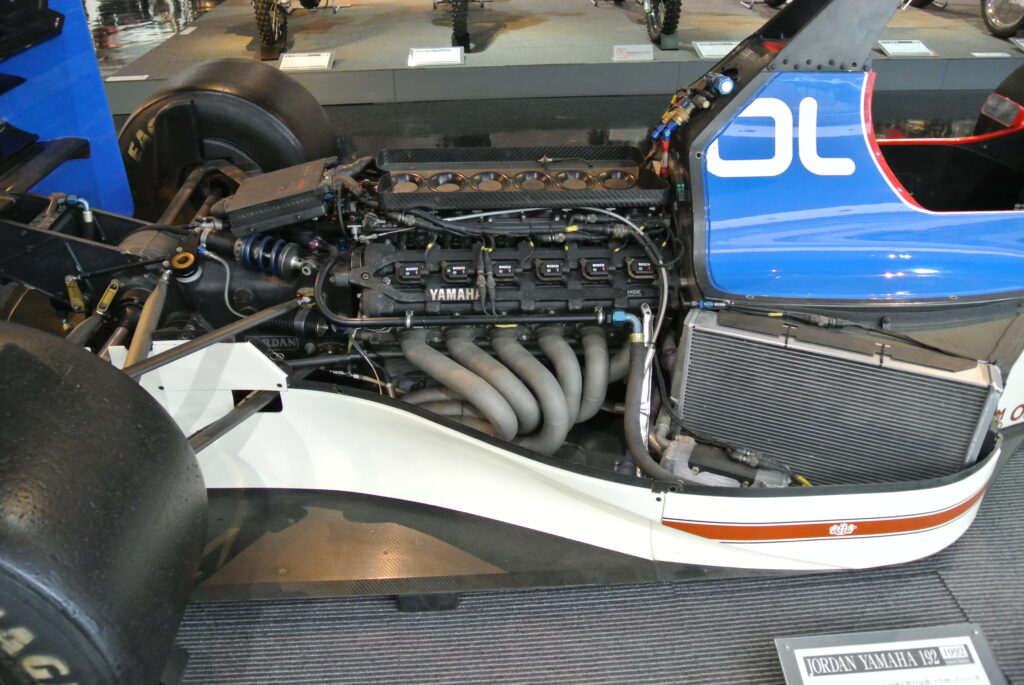

You need the engine and chassis to act as one aerodynamic unit. Intake and airbox placement affect volumetric efficiency; shorter, straighter intake trunks reduce flow losses and preserve charge density at high rpm.

Exhaust routing and diffuser interaction influence underbody pressure. You can tune the exhaust plume to energize the diffuser, increasing downforce without raising drag dramatically. That requires close packaging between the engine’s plumbing and the rear chassis aero elements.

Packaging decisions—fuel cell location, radiators, and structural members—change center of gravity and airflow paths. You must balance minimal frontal area with sufficient ducting; compressing components to lower drag can harm intake flow or cooling if done without CFD validation.

Cooling Technologies

Your cooling strategy directly constrains peak power and stint length. Radiator core size, fin density, and duct geometry set the heat rejection rate; you trade frontal area (and drag) for lower operating temperatures and safer power delivery.

Active and passive technologies coexist. Variable inlet louvers or cowl flaps let you open flow for heavy cooling needs and close them on straights to cut drag. You’ll also see internal duct shaping and vortex generators used to keep high-velocity air across heat exchangers, improving convective heat transfer without massively increasing duct size.

Thermal management ties into combustion stability. Cooler intake charge via effective intercooling raises knock margin and lets you run more aggressive ignition or boost maps. Monitor coolant and oil temperatures closely; overheating forces you to detune power, so aerodynamic cooling choices have direct effects on race pace.

Impact on Track Performance

Aerodynamic choices change lap time through both power delivery and mechanical grip. Increased downforce from optimized diffuser and wing interaction lets you carry higher cornering speeds, which reduces demand for repeated high-rpm acceleration and eases thermal stress on the engine.

Drag penalties affect straight-line speed and fuel consumption. You must quantify how much extra drag you accept for a given downforce gain; that determines gearing, engine mapping, and fuel strategy. Small drag reductions on long straights translate into lower average engine load and better fuel efficiency.

Transient airflow effects matter during overtakes and in traffic. You’ll experience intake pressure fluctuations and cooling airflow drops in the wake of other cars. Designing for stable performance in disturbed air—through robust intake and cooling locations—preserves engine output and prevents lap-to-lap variability.

Luxury Materials and Finishes

You will find materials chosen for both weight savings and thermal performance, plus finishes that communicate precision and status. Expect carbon composites, titanium and nickel alloys, and surface treatments tailored to heat, friction, and visual impact.

Use of Carbon Fiber and Exotic Alloys

Carbon fiber composites form structural and thermal components where stiffness-to-weight ratio matters most. In your engine bay you’ll see carbon intake plenums, heat shields, and aerodynamic covers made from woven prepreg layups cured under high pressure to reach consistent Tg (glass transition temperature). These parts cut mass and resist deformation under load.

Titanium appears in rods, fasteners, and exhaust systems because it combines low density with high yield strength. Nickel-based superalloys (Inconel variants) take the hottest duty in exhaust and turbine-adjacent areas, resisting creep at temperatures where aluminum and steel would fail. You should note trade-offs: machining costs and repair complexity rise with these alloys, but they preserve performance under extreme thermal cycling.

Aesthetic Detailing in Engine Construction

Finishes serve function and signaling; you can read quality in machining marks, coating choices, and color contrasts. Hard anodizing on aluminum components reduces wear and provides a matte, consistent tone that masks micro-abrasion. Gold or ceramic thermal coatings on brake ducts and exhausts visibly indicate thermal-management treatments and reduce radiant heat transfer to surrounding systems.

Precision milling leaves visible surface patterns on intake trumpets and valve covers that assert build quality. Fasteners often use bronze or titanium washers and are torqued to engraved specifications; these small details show assembly care and make routine inspection faster. You’ll also find laser-etched serial numbers on key parts to ensure traceability and authenticity.

Longevity and Durability

Materials are selected to maintain tolerances over thousands of cycles under high stress. Coatings such as physical vapor deposition (PVD) on camshafts and DLC (diamond-like carbon) on tappets reduce friction and wear, extending service intervals without sacrificing peak output. You will benefit from predictable wear patterns and straightforward replacement intervals when these treatments are applied.

Corrosion resistance matters for longevity too. Stainless and nickel alloys protect combustion and exhaust passages from oxidation, while sealed carbon components prevent moisture ingress. Still, you must accept that exotic materials require specific maintenance: specialized lubricants, torque sequences, and inspection tools to preserve the engineered lifespans.

Influence of F1 Engine Luxury on Road Cars

You will see F1-derived technologies in materials, energy systems, and exclusive partnerships that shape high-performance road cars. These influences appear in measurable gains: faster 0–100 km/h times, higher specific power, and lighter, stiffer structures.

Technology Transfer to Consumer Vehicles

F1 engine work pushes lightweight materials and thermal management into road cars. You find carbon-fiber structural parts, titanium fasteners, and ceramic coatings used in performance cars to reduce mass and tolerate higher temperatures.

Hybrid energy recovery concepts from F1’s ERS inform regenerative braking and battery-assist systems in sports sedans and SUVs. Manufacturers adapt control software and torque-fill strategies to deliver instant throttle response at low RPM.

You benefit from improved durability and service intervals because race-derived testing tightens tolerances and cooling designs. Brake-by-wire calibration and paddle-shifted transmissions also trace lineage to F1, giving you sharper shift times and more precise pedal feel in everyday driving.

Exclusive Hypercar Collaborations

Automakers collaborate directly with F1 teams or suppliers to create limited-run hypercars. These projects often share engine architecture, bespoke turbocharging, or hybrid packaging derived from race programs.

Examples include bespoke combustion tuning, track-grade cooling systems, and gearbox internals that mirror F1 layouts but meet road-legal noise and emissions rules.

You get factory-backed race calibration, dedicated aero, and performance telemetry on some models. Limited production runs also mean specialized aftercare: unique tooling, extended service support, and higher resale desirability for collectors who value authentic race-derived hardware.

Setting New Standards in Automotive Engineering

F1’s engineering benchmarks raise expectations for power density and thermal efficiency in road engines. You see specific power figures climb as designers apply higher boost pressures, advanced direct injection mapping, and lightweight reciprocating components.

Emissions and efficiency improve too, because F1’s move toward hybrid balance and energy management influences how manufacturers optimize combustion cycles and waste-heat recovery for street use.

Safety and testing methodologies transfer as well. You benefit from chassis integration practices, sensor networks, and data-driven validation that reduce development time and increase reliability across new performance models.

Challenges in Achieving F1 Engine Luxury

You face trade-offs between unrivaled performance, strict rules, and environmental responsibility. Meeting those demands requires massive investment, precise engineering, and strategic compromises.

Cost and Resource Constraints

You must fund development cycles that often run into tens of millions of dollars per season just for power-unit evolution. Prototype parts, exotic materials (titanium, Inconel, carbon-ceramic), and bespoke calibration tools drive unit costs far above road-car engines.

Teams also shoulder extreme operational expenses: dyno time, specialized test rigs, and highly skilled engineers and machinists. Those human resources are scarce and command premium salaries. Supply-chain bottlenecks for rare alloys or custom electronics can delay updates and force design compromises.

To control budgets you’ll prioritize which subsystems to optimize. That choice often means accepting marginal gains in less critical areas while concentrating investment on turbocharging, MGU-H/MGU-K integration, and combustion efficiency.

Regulatory Compliance

You must design within detailed FIA technical and sporting regulations that cap displacement, energy recovery, fuel flow, and component lifespans. Those limits restrict how far you can push peak power or rev ceilings without penalties.

Rule changes—such as the 2026 power unit overhaul and subsequent loophole clarifications—create uncertainty. You need rapid interpretation and legal-engineering responses to avoid noncompliance. Enforcement mechanisms like homologation and post-race scrutineering force conservative choices for reliability.

Balancing maximum performance and legal risk requires rigorous verification: telemetry analysis, pre-race checks, and traceable documentation for every component. Noncompliance can result in grid penalties, fines, or disqualification, so defensive engineering becomes part of your development strategy.

Sustainability Initiatives

You must reduce lifecycle carbon footprint while preserving the “luxury” performance image. The move to biofuels, higher electrical recovery, and stricter fuel-flow rules changes combustion calibration and fuel chemistry demands.

Hybrid systems increase complexity: you need battery packs, power electronics, and heat-management systems that add weight and packaging challenges. Recycling and responsible sourcing of rare materials (lithium, cobalt, rare-earth magnets) influence supplier choices and cost.

To reconcile performance with sustainability, you’ll implement measures such as optimized energy deployment maps, efficient heat recovery, and use of sustainable fuels approved by the FIA. Those measures often require additional testing and validation to retain the tactile and auditory characteristics fans and sponsors expect.

The Future of Luxury F1 Engines

You will see engines that balance extreme lap-focused power with strict efficiency, carbon-reduction tech, and bespoke manufacturing. Expect tighter integration between chemical energy, electrical hybrid systems, and bespoke software to define what “luxury” means on track.

Innovations in Green Technologies

You will encounter hybrid systems that increase electric deployment per lap while cutting fuel mass and carbon emissions. New regulations push for higher electrical energy recovery (MGU-K and MGU-H-like systems) and mandated sustainable fuels that match race energy density but reduce lifecycle CO2.

Manufacturers adopt synthetic and e‑fuel blends certified to lower net carbon; these fuels let combustion architectures retain high thermal efficiency while meeting decarbonization targets. Battery and supercapacitor hybrids appear in packaging optimised for weight distribution and rapid charge-discharge cycles.

Materials shift toward recycled high-strength alloys and carbon composites to offset added hybrid hardware mass. You should expect teams to trade peak combustion power for better overall lap energy management, using software to orchestrate when and how electrical boosts deploy.

Predicted Trends in Engine Engineering

You will notice engines designed as integrated power units, not standalone ICEs. Tight co-design of combustion chambers, turbocharging, heat recovery, and power electronics reduces losses and raises system-level efficiency.

Thermal-management advances—such as looped heat exchangers and localized phase-change materials—enable higher continuous power output without enlarging radiators. Precision additive manufacturing lets engineers produce complex cooling channels and lightweight geometry that were impossible with traditional machining.

Software-defined engine maps become more central. Teams will use deterministic real-time control to balance fuel flow, turbo boost, and electric assist per corner. Expect standardized safety and cost caps to limit runaway spending while still rewarding engineering finesse.

Evolving Definitions of Performance and Luxury

You will redefine luxury as measurable efficiency, bespoke drives, and refined delivery rather than only raw horsepower. Luxury in F1 will mean seamless torque fill from hybrid systems, near-instantaneous transient response, and audible yet regulated combustion character.

Customization will extend to team-specific sound tuning, ergonomic driver interfaces, and tailored power curves for each circuit. Buyers of road-derived hypercars will demand tech transfer: the same combustion strategies and lightweight manufacturing that win in F1 will carry prestige value.

Servicing and telemetry will become part of the luxury package, with predictive maintenance, over-the-air calibration, and trackside concierge engineering offered to factory-backed customers and partners.