Mesin F1 Mewah dengan Tenaga Besar dan Efisiensi Bahan Bakar Tinggi: Engineering Insights on High-Power, Fuel-Efficient Luxury F1 Engines

You want a machine that feels indulgent and relentless at once: a luxury F1 engine blends extreme horsepower with hybrid systems and fuel tech that squeeze efficiency without sacrificing speed. These engines deliver the raw power of over 1,000 hp in peak conditions while using advanced hybrid recovery and cleaner fuels to cut consumption and emissions, letting teams chase performance and sustainability simultaneously.

Expect the article to unpack how teams marry lightweight engineering, aerodynamics, and energy-recovery systems to produce blistering acceleration and race-distance efficiency. You’ll see how regulations, materials, and innovations from top teams shape both track dominance and road-car technology, revealing why luxury and fuel efficiency now go hand in hand.

Overview of Luxury F1 Cars

Luxury F1 cars combine peak performance with top-tier engineering and materials to deliver exceptional power, efficiency, and driver-focused refinement. You will find advanced hybrid power units, carbon-fiber construction, and bespoke componentry that prioritize both lap time and premium detail.

Defining Luxury in Formula 1

Luxury in F1 means more than price or branding; it means uncompromising engineering that enhances performance and driver experience. You expect handcrafted carbon-fiber monocoques, precision-machined suspension elements, and tailor-made cockpit fittings that match a driver’s ergonomics and control preferences.

Materials and finish matter: titanium fasteners, aerospace-grade alloys, and heat-resistant composites reduce weight while raising durability. Electronics and telemetry are tuned for responsiveness and clarity, giving you immediate feedback and control. Luxury also appears in service: rapid pit-stop systems, bespoke setup support, and logistics that keep the car at peak condition across a season.

Key Features Distinguishing Modern F1 Cars

Modern luxury F1 cars center on the hybrid power unit, energy recovery systems, and aerodynamic sophistication. You will see a turbocharged V6 combined with MGU-K and MGU-H units that harvest kinetic and thermal energy, increasing power while improving fuel efficiency.

Aerodynamics use precisely engineered wings, diffusers, and floor designs to generate downforce with minimal drag. Suspension and transmission systems feature ultra-fast paddle-shift gearboxes and adaptive damping to maintain tire performance. Electronics integrate real-time telemetry, allowing engineers to tune power deployment, fuel maps, and brake-by-wire calibration during sessions.

Big Power Engine Technologies

The most relevant advances combine electric energy recovery, forced induction, and ultra-light materials to boost peak power while cutting fuel use and mass. You’ll see how hybrid systems add usable kilowatts, how turbochargers shape torque and response, and which materials let you extract more power per kilogram.

Hybrid Power Units Explained

Hybrid power units pair a 1.6L turbocharged V6 with two energy-recovery systems: the MGU-K (kinetic) and MGU-H (heat). The MGU-K recovers braking energy and can add up to ~120 kW of instant drive power to the crankshaft, while the MGU-H harvests exhaust-turbo energy to spool the turbo and recharge batteries.

You control energy deployment through mapped strategies that balance battery state-of-charge, boost demand, and fuel flow limits. FIA rules cap fuel flow and total fuel per race, so hybrids supply the extra transient power that internal combustion alone cannot without exceeding consumption limits.

Key benefits you’ll notice: immediate torque fill at corner exits, reduced turbo lag, and higher average lap power without proportionally higher fuel use. Maintenance and thermal management focus on cooling the battery, inverters, and MGU-H bearings to sustain repeated high-power cycles.

Turbocharging and Performance

Modern F1 turbos run at very high pressures and speeds; the MGU-H lets teams control turbo speed electrically, preventing lag while maintaining peak boost. That means you get rapid pressure build-up at low rpm and consistent peak pressure at high rpm without overfueling.

Turbo geometry and intercooler efficiency directly affect charge-air temperature and detonation margins. You’ll evaluate compressor maps, turbine efficiency, and heat-exchanger performance because cooler, denser intake charge delivers more combustion energy per unit of fuel.

Teams optimize spool via wastegate strategy and MGU-H intervention, trading a small electrical energy draw for faster spool and better drivability. Component durability matters: turbine alloys, shaft balancing, and bearing lubrication must tolerate transient shocks above 150,000 rpm.

Engine Materials and Lightweight Innovation

You’ll find extensive use of titanium, Inconel, and carbon-fiber composites across rotating assemblies, exhausts, and the engine cover to cut mass while keeping strength. Titanium connects and fastens with high fatigue resistance; Inconel handles exhaust temperatures above 900°C without creep.

Pistons and connecting rods use forged aluminum alloys and asymmetric designs to reduce reciprocating mass and lower inertia. Cylinder liners and coatings—like Diamond-Like Carbon (DLC) on bearings—reduce friction and allow higher mean piston speeds safely.

Structural parts hybridize metal and composite to optimize stiffness-to-weight ratios. Every gram saved lets you reallocate mass to ballast placement for better handling, or to add cooling hardware without exceeding minimum weight targets.

Advancements in Fuel Efficiency

You’ll read about how modern F1 extracts extra energy from braking and exhaust, uses bespoke sustainable fuel blends, and applies race-day strategies to stretch every drop of fuel. These developments focus on measurable gains: higher MJ harvested, lower grams-per-kilometer emissions, and lap-time-neutral consumption savings.

Energy Recovery Systems in F1

You rely on two main recovery systems: MGU-K (kinetic) and MGU-H (heat).

The MGU-K captures braking energy and converts it to electrical energy, delivering up to 120 kW back to the powertrain for acceleration bursts. Teams tune deployment maps so recovered kW supplements the internal combustion engine (ICE) at strategic points on the lap.

The MGU-H harvests turbine exhaust heat and can either store energy or spin the turbocharger to eliminate lag.

That capability reduces fuel use by enabling the ICE to run leaner during acceleration and by recovering energy that would otherwise be wasted as heat. Efficient cooling and control electronics are critical; you’ll see differences in lap consistency when teams manage thermal limits well.

Optimized Fuel Formulations

You should expect modern F1 fuels to be high-octane, tightly specified, and increasingly based on sustainable feedstocks.

Fuels must meet FIA homologation but teams work with suppliers to optimize energy density, combustion speed, and knock resistance within those rules. Small changes in calorific value or volatility translate to measurable lap-time and fuel-consumption differences.

Sustainable fuel blends (e-fuels or bio-derived components) aim to match conventional performance while cutting lifecycle carbon.

Those fuels often require recalibration of ignition timing, injection pressure, and turbo boost strategies. You’ll notice engineers log combustion metrics and adjust maps to keep thermal efficiency high without exceeding fuel-flow or total-fuel limits.

Fuel Management Strategies During Races

You control fuel strategy through real-time telemetry, engine maps, and driver coaching.

Teams monitor instantaneous fuel flow (limited by FIA rules), cumulative fuel used, and projected consumption to the finish. Engineers use those inputs to switch between conservative and aggressive maps, optimizing lap times without breaching the total fuel allowance.

Drivers adjust driving style on instruction: lift-and-coast, short-shifting, or trimming ERS deployment windows to save fuel.

Pit strategies also hinge on fuel load decisions—lighter starts improve lap time but compress strategy options. You’ll see teams balance stint length, traffic, and track evolution to extract the best combination of pace and efficiency.

Integration of Luxury and Performance

You get a cockpit that balances premium comfort with race-grade function. Materials, layout, and controls prioritize driver focus while delivering tactile luxury.

Interior Design and Ergonomics for Drivers

You sit in a bespoke carbon-fiber monocoque seat contoured to your exact body dimensions or adjustable to a tight tolerance. Padding uses layered foams and temperature-regulating fabrics to reduce fatigue during long stints without compromising lateral support.

Controls and displays position within a narrow reach envelope. The steering wheel integrates tactile switches, rotary dials, and a high-resolution telemetry display so you can adjust engine maps, hybrid deployment, and brake bias without taking your hands off the wheel.

Sound insulation targets low-frequency rumble while preserving necessary engine and ERS cues. Ventilation channels and coolant lines route through the shell to manage your microclimate during high-load runs.

Precision Engineering in Controls

You interact with actuators and linkages designed for sub-millimeter repeatability. Shift paddles use load-bearing materials and quick-return mechanisms to deliver consistent gear changes under high G and heat.

Brake and throttle systems feature redundant hydraulics and high-bandwidth sensors. Pedal feel calibrates through adjustable leverage ratios and friction materials so you can tune modulation for wet or dry conditions.

Electrical architecture centers on deterministic wiring and low-latency CAN/ethernet nodes. That ensures your inputs—gear changes, ERS deployment, differential settings—translate to immediate, predictable vehicle responses.

Aerodynamic Enhancements for Speed and Efficiency

Aerodynamic upgrades reduce drag on straights, increase downforce in corners, and recover usable energy through heat and pressure management. You will see targeted changes to wings, underfloor tunnels, and cooling inlets that directly affect lap time and fuel consumption.

Impact of Aerodynamics on Power Consumption

Airflow shapes how much engine power you must use to reach and hold speed. Lower drag on straights cuts required wheel power, so the power unit spends less fuel per kilometer; teams quantify this as reduced brake-specific fuel consumption during sustained top-speed runs.

Downforce increases cornering grip but raises aerodynamic load, so you trade extra lateral and longitudinal forces for higher tyre grip and usually a modest rise in fuel use. Engineers balance wing angle and underfloor pressure to hit the target lap-time gain per tenth of a kilogram of fuel burned.

Cooling and heat-management also affect consumption. Larger or poorly shaped inlets raise drag and force the cooling system and fans to extract more energy from the power unit. You should expect teams to refine cooling duct geometry and internal baffling to minimize parasitic losses while keeping temperatures safe.

Active Aero Components

Active aero systems let you change aerodynamic behaviour during a lap to optimize both speed and efficiency. Deployable elements such as flaps and movable DRS-type plates reduce drag on straights and restore higher downforce in corners, lowering fuel used for a given lap time on mixed circuits.

You must account for actuator power draw and control-system weight; modern implementations keep electrical or hydraulic consumption minimal compared with the aerodynamic gains.

Adaptive underfloor and vortex-management devices tune ground-effect pressure dynamically. When properly controlled, these devices preserve cornering grip without permanently increasing drag, so you use less fuel across a stint. Teams integrate sensors and fast control loops to switch modes seamlessly, prioritizing reliability and repeatability under race conditions.

Sustainability Initiatives and Future Trends

You will find targeted changes in materials, manufacturing, and powertrain development that cut lifecycle emissions and keep racing performance high. Expect concrete shifts in supply chains, recycling practices, and power-unit architecture that affect teams, suppliers, and fans.

Eco-Friendly Materials in F1 Manufacturing

Teams and suppliers now prioritize low-carbon and recyclable materials for chassis, bodywork, and paddock infrastructure. You’ll see increased use of recycled carbon-fiber composites and certified low-embodied-carbon resins in non-structural components to reduce upstream emissions without compromising stiffness where it matters most.

Manufacturers are auditing supply chains to source aluminum and titanium with better smelter footprints and greater recycled content. You should expect more modular components designed for disassembly so parts can be refurbished or recycled between seasons.

Operational changes matter too: additive manufacturing (3D printing) reduces waste by producing near-net shapes, and solvent-free paints and water-based coatings cut volatile organic compound emissions in the factory and garage. Teams publish Environmental Management System (EMS) data to track progress and verify improvements.

Hybrid and Electric Developments on the Horizon

Hybrid power units remain central; you should expect incremental increases in electrical energy recovery and storage capacity within the current packaging and weight constraints. Improvements to the MGU-K and MGU-H systems will boost recuperation efficiency, letting engines deliver the same or higher peak power with less fuel consumption.

Sustainable drop-in fuels compatible with existing ICE architectures will scale through 2026–2030, reducing lifecycle CO2 when paired with hybrid systems. Parallel research explores higher-voltage electrical systems and improved battery chemistries for faster discharge and regenerative performance during race duty cycles.

You will also notice advancements in race logistics and paddock electrification—solar, on-site battery storage, and low-carbon grid connections—to cut event emissions. These changes preserve the high-revving character you expect while steadily lowering the sport’s carbon intensity.

Influence of Regulations on Engine Power and Fuel Usage

Regulations set hard limits on combustion output, hybrid contribution, and fuel mass, which directly determine how much power you can extract and how you must use fuel during a race. They force trade-offs between peak horsepower, thermal efficiency, and energy recovery strategies.

FIA Technical Directives Shaping Efficiency

The FIA mandates engine architecture specs, fuel flow limits, and strict component quotas that control your peak and sustained power. For 2026-style rules, the internal combustion engine (ICE) displacement and turbocharging geometry are regulated, while fuel flow and total fuel allowance per race cap how much usable energy the ICE can deliver.

You must optimize combustion timing, compression, and friction reduction to squeeze more watts from each gram of fuel. Hybrid rules increase the electrical energy budget; that pushes you toward higher-efficiency engines rather than just higher peak torque.

Key regulated items you encounter:

- Fuel mass per race and maximum fuel flow rate.

- Limits on ICE rpm and turbocharger parameters.

- Quotas on power unit components to limit development pace.

These directives require targeted engineering: focus on thermodynamic efficiency, reduced pumping losses, and a tight integration with the battery/MCU control for regenerative harvesting.

Balancing Compliance and Innovation

You can’t exceed the rulebook, but you can innovate within it. Teams invest in novel combustion chamber shapes, advanced coatings, and optimized cam/phasing strategies to meet the fuel limits while improving output.

Hybrid system simplification in recent regulations removes some complex recovery units, so you must achieve gains through software, materials, and precise energy management. That means software algorithms that prioritize when to deploy electric boost and when to harvest, maximizing lap time within the electrical energy allowance.

Practical approaches you’ll see teams use:

- Modeling-driven calibration to trade peak power for better efficiency over a stint.

- Lightweight, heat-resistant materials to reduce losses and recover more waste heat.

- Integrated control strategies linking ICE maps with battery state-of-charge to avoid wasted fuel.

These techniques let you achieve competitive power and fuel economy while staying fully compliant with FIA technical directives.

Notable Teams Pioneering Luxury and Efficiency

You will read about two teams that combine premium engineering with high thermal efficiency and hybrid performance. Both focus on extracting maximum power per unit of fuel while keeping drivability and reliability for race distance.

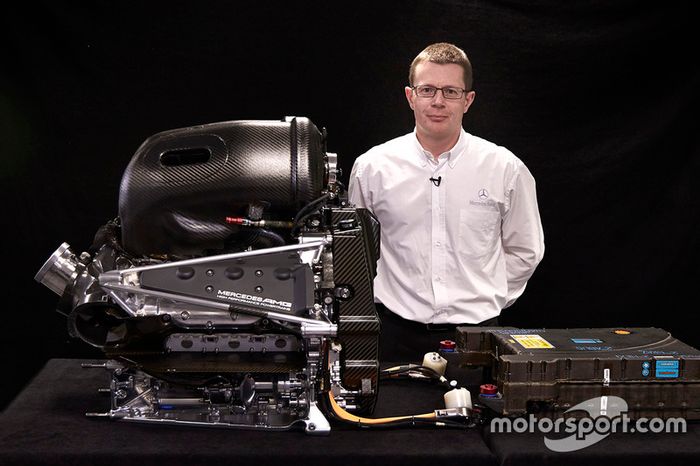

Mercedes-AMG PETRONAS Advancements

Mercedes has pushed thermal efficiency above 50% in recent power units, letting you get more energy from each liter of fuel. They pair a highly optimized internal-combustion engine (ICE) with an MGU-K and MGU-H that recover kinetic and heat energy; this reduces fuel consumption while boosting lap-time power delivery.

Their cylinder-head design, turbocharger packaging, and combustion-chamber calibration aim to shorten transient response and lower pumping losses. You benefit from a powertrain that delivers strong mid-range torque for corner exits and rapid electric torque fill during throttle transitions. Reliability programs and track-data-driven component life management keep performance consistent across race weekends.

Ferrari Innovations in Powertrain

Ferrari concentrates on combustion efficiency and compact turbo layout to minimize thermal losses and rotational inertia. You’ll notice their focus on high-pressure direct injection, bespoke turbocharger mapping, and lightweight rotating assemblies that improve rev response and peak power density.

Their hybrid system balances aggressive energy recovery with battery weight constraints to keep center-of-gravity and handling unchanged. Ferrari’s integration work—engine, ERS, and cooling—reduces parasitic losses and keeps package size tight for aerodynamic benefits. That approach gives you a power unit that is both powerful on straights and tractable exiting slow corners.

Impact on Consumer Automotive Technology

You encounter F1-derived hybrids in many modern cars through energy recovery systems that blend combustion and electric power. These systems increase peak power while lowering fuel use, so you get better performance without proportionally higher consumption.

Aerodynamic advances from F1 influence body shapes and undertrays on road cars. You benefit from reduced drag and improved stability, which translate to lower fuel use at speed and more predictable handling.

Safety innovations such as HANS-inspired restraint concepts, advanced helmets research, and multi-stage airbags began in racing and now protect you in everyday vehicles. These technologies raise passive safety standards and improve crash outcomes.

You see materials and braking tech trickle down too: carbon-ceramic brakes for fade resistance, lightweight composite panels for mass reduction, and heat-management solutions that extend component life. These features help your car accelerate, stop, and last more efficiently.

Key transfer mechanisms:

- Research partnerships between manufacturers and racing teams accelerate development.

- Regulation-driven constraints in F1 (fuel limits, efficiency rules) force high-efficiency solutions that adapt well to road use.

- Motorsport testing provides extreme conditions that validate durability and reliability for consumer applications.

You should expect continued trickle-down of turbocharging strategies and synthetic fuels research. These aim to keep internal combustion relevant while improving efficiency and lowering lifecycle emissions.