Mengulas Mesin F1 Mewah yang Digunakan Tim-Tim Papan Atas Formula One — Technical Breakdown and Performance Insights

You’ll get a clear look at what makes the engines of top F1 teams truly luxurious: advanced hybrid systems, exotic materials, and bespoke software that squeeze maximum power and efficiency from every lap.

These power units combine cutting-edge engineering and race-proven electronics to deliver unmatched performance and technological leadership in motorsport.

You’ll explore how teams like Red Bull, Mercedes, and Ferrari tailor engine design to their strategies, what performance metrics matter most, and how those innovations trickle down into road cars. Expect comparisons of manufacturers, the real engineering challenges behind high-end F1 engines, and why these units set the benchmark for automotive technology.

Overview of F1 Luxurious Engines

You will read how top-tier power units combine extreme power density, hybrid energy recovery, and bespoke supplier partnerships. Expect details on design traits, cutting-edge systems, and how those engines evolved into today’s road-map for performance and efficiency.

Definition and Characteristics of F1 Luxury Engines

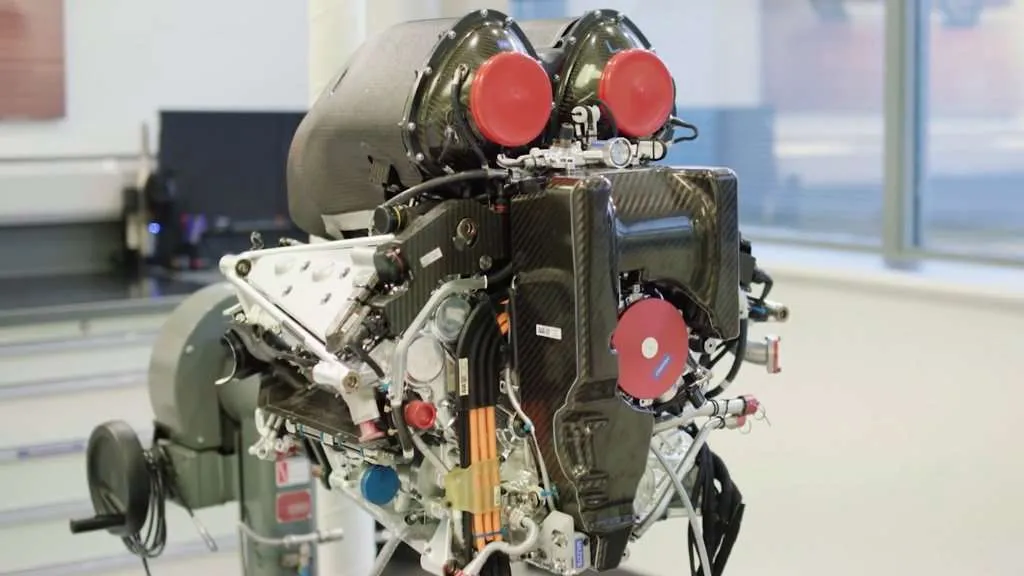

An F1 “luxury” engine refers to the most advanced factory-spec power units used by front-running teams. These units are 1.6‑litre V6 turbo hybrid power units with a combustion engine, MGU‑K (kinetic recovery), MGU‑H (heat recovery), energy store, and control electronics.

You should note they target maximum power per kilogram and thermal efficiency above 50%, while complying with strict FIA limits on rpm, fuel flow, and component lifetimes.

Key characteristics:

- Power density: peak combined output often exceeds 1000 PS in qualifying trim.

- Hybrid integration: MGU‑H and MGU‑K recover and redeploy energy to boost lap time and lower fuel use.

- Materials and manufacturing: titanium, carbon composites, and exotic alloys reduce weight and withstand extreme temperatures.

- Software: real‑time engine maps and driver-selectable modes tailor performance across tracks.

Technological Innovations in F1 Engine Design

You will see innovations focused on energy recovery, turbocharger control, and software-driven optimization. The MGU‑H remains unique in motorsport, controlling turbo lag and harvesting exhaust heat into electrical energy.

Advances in lubrication, cooling microchannels, and ceramic coatings push reliability while reducing parasitic losses.

Notable systems and methods:

- Turbo and MGU‑H coupling for instantaneous response and variable turbine behavior.

- Integrated power electronics with strict homologation to ensure predictable control.

- High-precision fuel injection and direct-injection strategies for efficiency and combustion stability.

- Simulation and AI‑assisted calibration that shortens development cycles and fine-tunes maps for tire and aero profiles.

Historical Evolution of Luxury Power Units in Formula One

You should track the shift from atmospheric V8/V10/V12 engines to today’s hybrid V6 turbo units. In the 2000s, teams prioritized raw displacement and rpm; from 2014 the sport mandated 1.6‑litre turbo hybrid units, forcing a focus on efficiency and electrical recovery.

Suppliers and works partnerships grew more strategic: manufacturers like Mercedes, Ferrari, Renault, and later collaborations such as Red Bull–Ford pursued bespoke architectures and software ecosystems to gain tenths per lap.

Milestones:

- Pre‑2014: high‑revving naturally aspirated engines emphasized peak power.

- 2014 rule change: introduction of MGU‑H and MGU‑K with strict fuel flow limits.

- 2020s: emphasis on cost caps, software control standards, and supplier consolidation, while maintaining competitive differentiation through thermal efficiency and hybrid deployment strategies.

Top Formula One Teams and Their Signature Engines

You will read which teams pair chassis design with distinctive power unit philosophies, how those engines deliver peak performance, and where reliability or partnership choices matter most.

Scuderia Ferrari’s Power Units

Ferrari develops and manufactures its own power units at Maranello, combining an inline layout with strong thermal efficiency and a focus on mid-range torque. You notice Ferrari emphasizes drivability for street-circuit traction and long-stint engine maps, which helps its cars exit slow corners with more acceleration than rivals.

Ferrari’s units include a high-performance ERS (Energy Recovery System) integrated tightly with the internal combustion engine to boost peak power and improve lap-to-lap consistency. You should watch for updates during the season that target both combustion efficiency and ERS deployment to close gaps in qualifying and race pace.

Reliability has oscillated across recent seasons, so Ferrari often brings iterative hardware and software updates rather than wholesale redesigns. That strategy balances risk and development cost while keeping upgrade windows aligned with key races.

Mercedes-AMG’s Engine Excellence

Mercedes-AMG Powertrains focuses on peak power density and superior hybrid integration, delivering strong top-end speed and efficient energy deployment. You will notice Mercedes engines excel on long straights and maintain consistent thermal control under heavy load.

Mercedes pairs a robust MGU-K and MGU-H system with advanced turbocharger technology to reclaim exhaust energy and smooth power delivery. Their approach prioritizes qualifying power and long-run stability, giving drivers predictable performance across variable conditions.

Mercedes also invests heavily in reliability engineering and simulation, reducing the frequency of in-season failures. When you analyze lap times, Mercedes’ advantage often shows not just in raw horsepower but in how consistently that power is available across a race weekend.

Red Bull Racing’s Technological Partnerships

Red Bull Racing combines a chassis focused on aerodynamic downforce with externally sourced power units, most recently through a close technical partnership that emphasizes bespoke integration. You see Red Bull optimize gearbox, cooling, and mounting to extract maximum performance from partner engines.

The team’s strategy centers on aerodynamics-first design, meaning engine selection and packaging adapt to support high downforce setups. Red Bull also collaborates on engine development priorities, pushing for specific torque curves and throttle response that suit its chassis balance.

Expect Red Bull to target targeted upgrades that improve ERS calibration and cooling efficiency rather than wholesale engine replacements mid-season. You benefit from the team’s consistent focus on matching power delivery to aerodynamic strengths, which often translates to superior corner exit speeds.

Core Features of Luxury F1 Engines

You’ll read about hybrid energy systems that recover and deploy power, the exotic materials and micrometer-level tolerances used in construction, and the tight aerodynamic packaging that shapes cooling and airflow.

Hybrid Technology and Energy Recovery Systems

You depend on the power unit’s hybrid elements for both peak speed and lap-to-lap efficiency. Modern F1 power units combine a 1.6‑litre turbocharged V6 internal combustion engine (ICE) with two motor-generator units: the MGU‑K (kinetic) and MGU‑H (heat). The MGU‑K harvests braking energy and can supply up to 120 kW directly to the drivetrain, while the MGU‑H captures turbo heat to control spool and charge the battery without fixed power limits.

Energy storage is a high‑density lithium‑ion system with strict weight and capacity rules; you’ll notice strategy differences in how teams deploy stored energy for overtakes or lap time. Electronic control units manage energy flow, torque fill, and battery state-of-charge within regulatory constraints to maximize usable power and reliability.

Materials and Precision Engineering

You expect components to use titanium, Inconel, and carbon composites to save weight while retaining strength at extreme temperatures. The ICE uses forged steel and aluminum alloys, with nitrided or coated internals to resist wear at >15,000 rpm. Turbo internals and exhausts run on nickel‑based superalloys (Inconel) to tolerate >900°C gas temperatures.

Manufacturing tolerances sit in microns: cylinder bore finishes, crankshaft balance, and valve timing are optimized on precision rigs. Additive manufacturing appears in low‑volume brackets and cooling passages. Teams also carry bespoke calibration maps and dyno data to squeeze reliability from tightly stressed parts while meeting the per‑engine usage limits.

Aerodynamics and Engine Packaging

Your engine isn’t just power; it’s an aerodynamic element. Teams package the power unit to minimize frontal area and shape internal airflow for radiators, oil coolers, and intercoolers. Sidepod geometry, ducting paths, and heat exchangers sit tight to the gearbox and chassis, balancing cooling requirements against drag.

You’ll see bespoke heat management: CFD-driven duct shapes, variable inlets, and carefully routed exhausts that influence diffuser and rear‑wing performance. Compact packaging reduces center‑of‑gravity and improves weight distribution, but forces tradeoffs—overcooling risks and thermal stress can force larger openings, increasing drag. Teams iterate both hardware and cooling maps to maintain optimum temperatures with minimum aerodynamic penalty.

Performance Metrics and Capabilities

You will find concrete figures on peak power, durability targets, and fuel-consumption strategies that define modern F1 power units. These metrics determine lap time potential, race consistency, and compliance with 2025 hybrid-era regulations.

Horsepower and Torque Specifications

Top F1 power units combine an internal combustion engine (ICE) and hybrid systems to produce peak outputs typically between 950–1050 PS (metric horsepower) at peak ERS deployment during 2024–25 development cycles. The 1.6‑litre V6 turbo ICE alone produces roughly 750–800 PS at high rpm, while the Energy Recovery System (ERS) contributes the remaining 200–300 PS in short bursts.

Peak torque figures vary with turbo boost and hybrid deployment. You can expect combined torque to exceed 700–800 Nm instantaneously when ERS is engaged, but usable torque across a lap depends on boost maps and drivability. Teams tune torque delivery to avoid wheelspin out of slow corners and to manage tyre degradation.

Reliability and Lifespan

Teams design power units to last multiple race weekends; regulations mandate limited engine components per season, so durability matters. A single power unit is often expected to cover 3–5 grands prix under 2025 transitional rules before penalty risks arise.

Reliability strategies include conservative thermal margins, reinforced bearings, and engine-mapping that limits peak stresses during race stints. You should expect teams to trade a small percentage of peak power for longer lifespan when tracking championship durability budgets. Failure modes that teams guard against include turbocharger bearing wear, MGU‑H overheating, and detonation in the ICE.

Fuel Efficiency Advancements

Fuel flow limits and sustainability targets push teams to extract more energy per kilogram of fuel. Modern F1 engines achieve higher thermal efficiency than road cars, with effective fuel conversion improvements driven by combustion calibration, hybrid recuperation, and optimized turbocharging.

You will see strategies such as brake-energy recovery to reduce ICE load, leaner combustion at cruising sections, and map-based staging to preserve fuel for attack laps. Fuel-saving measures must balance with lap-time demands; teams use real-time fuel consumption telemetry and predictive models to adapt strategy across practice, qualifying, and race phases.

Comparing Engine Manufacturers in Formula One

You will find differences in peak power delivery, hybrid efficiency, and reliability records across manufacturers. Pay attention to how each supplier balances ICE performance with MGU-K/H integration and cooling packaging to suit their partner teams.

Ferrari Versus Mercedes

Ferrari focuses on high combustion efficiency and an ICE character that delivers strong mid-to-high RPM torque. That suits tracks requiring long straights, but historically it required careful cooling design to avoid overheating under sustained load.

Mercedes emphasizes hybrid integration, with an MGU-H concept and energy deployment that has often produced superior lap-by-lap electrical power. Their traction and drivability out of slow corners typically give teams an advantage in qualifying and race starts.

Compare metrics that matter to you:

- Power unit components: ICE, MGU-K, MGU-H, turbo, battery.

- Strengths: Ferrari — top-end torque and packaging for aero; Mercedes — hybrid recovery and deployment, thermal management.

- Trade-offs: Ferrari may need more cooling surface area; Mercedes units can be more complex and sensitive during development.

Red Bull Powertrains and Honda

Red Bull Powertrains inherited Honda’s hybrid core and adapted it for in-house development focused on chassis integration. You’ll notice Red Bull prioritizes compact packaging to improve aero around the sidepods and diffuser.

Honda’s prior approach emphasized lightweight construction and efficient turbocharger mapping to reduce lag. Red Bull retained that philosophy but shifted priorities to optimized energy flow for race pace under heavy aero load.

Key practical points:

- Integration: Red Bull optimizes housing and ancillaries to reduce aerodynamic drag.

- Reliability: Honda brought strong reliability gains before handover; Red Bull continues incremental updates.

- Tuning: Teams tune ERS deployment patterns to favor sustained lap times over single-lap peak power.

Renault and Alpine Developments

Renault (branded as Alpine for works entry) targets balanced performance with a focus on controllable torque and engine braking characteristics. That approach helps you manage tyre life on abrasive circuits.

Their development path emphasizes cost-controlled upgrades and consistent reliability rather than radical power bursts. You’ll see incremental gains in turbo efficiency and battery management across seasons.

Operational takeaways:

- Strengths: Predictable power delivery, conservative thermal envelope, and adaptability to different chassis.

- Limitations: Generally a step behind top suppliers in peak hybrid output and straight-line horsepower.

- Development focus: Turbocharger mapping, MGU-K replenishment, and packaging improvements to reduce aerodynamic penalties.

Influence of F1 Engine Technology on Automotive Industry

F1 engine advances have shortened development cycles and pushed measurable gains in efficiency, materials, and electronics that appear in road cars. Expect improvements in hybrid powertrains, thermal efficiency, and real-time vehicle data as the most tangible outcomes.

Technology Transfer to Production Cars

You see direct transfers from F1 in hybrid systems, turbocharging, and electronics. The current V6 turbo-hybrid power units proved F1 hybrids can deliver high specific power while using much less fuel, and manufacturers adapted similar downsized turbo-hybrid architectures for performance road cars and electrified SUVs.

Materials and cooling strategies also cross over. Lightweight alloys, carbon composites for ancillary components, and ceramic coatings developed to withstand F1 thermal loads reduce weight and improve durability in street engines. Brake-by-wire and torque management software created for race integration now inform traction-control and regenerative strategies in production vehicles.

Practical examples matter: paddle shifters, advanced telemetry for predictive maintenance, and energy-recovery control logic first refined in racing appear in premium cars’ transmissions, driver-assist calibrations, and battery-management systems.

Sustainability Initiatives

You can trace efficiency gains directly to F1’s push for lower fuel consumption and hybridization. F1’s thermal-efficiency targets and energy-recovery systems force engineers to extract more usable work per kilogram of fuel, which translates to higher-compression designs and more efficient combustion mapping in road engines.

F1 testing of sustainable fuels accelerates adoption for public use. Blends of bio-derived and synthetic e-fuels trialed in racing provide real-world validation for lower-carbon fuels in legacy internal-combustion fleets.

Lightweighting and improved cooling lower lifecycle emissions by reducing energy use during operation. In addition, F1-grade battery and energy-management expertise helps automakers optimize hybrid battery sizing, charge rates, and longevity — all relevant to reducing total ownership emissions for electrified models.

Future Trends in Engine Innovation

You should expect tighter integration between electrification and combustion for several years. F1’s hybrid architecture will inspire more powerful, smaller combustion units paired with high-power electric motors and advanced power electronics in road cars.

Software-defined control will expand. Real-time sensor fusion and predictive energy allocation from F1 will enable vehicles to shift performance and efficiency characteristics on the fly, improving urban fuel use and track performance alike.

Finally, alternative fuels and materials research in F1 will continue to guide commercial adoption. As teams validate e-fuels, hydrogen components, and novel thermal coatings under race stress, manufacturers will have vetted paths to scale these technologies into passenger-vehicle production.

Challenges in Developing Luxurious F1 Engines

You face tight technical and commercial limits when building a top-tier Formula 1 power unit. Regulatory rules, constrained budgets, and complex supplier relationships shape every design choice you make.

Regulatory Constraints

FIA rules tightly bound engine architecture, fuel use, and emissions. You must design within a prescribed hybrid layout and strict fuel flow limits, which restrict peak combustion power and force optimization of energy recovery systems. Meeting maximum allowed fuel mass and flow means you cannot simply raise horsepower; you must improve thermodynamic efficiency, turbocharger mapping, and electric motor deployment to extract gains.

Mandatory homologation windows and component life requirements also limit iterative hardware changes during a season. You need to plan upgrades months in advance and justify them against parc fermé-style restrictions. Compliance testing, teardown inspections, and penalty risks add development overhead and legal exposure.

Budget Limitations

Even “luxury” engines must be justified inside budget caps and internal financial ceilings. You will face trade-offs between investment in exotic materials, machining tolerances, and development manpower. Teams allocate finite R&D funds across combustion, hybrid software, and cooling; overspending in one area forces compromises elsewhere.

Cost controls drive reuse of proven subassemblies and reliance on simulation rather than expensive prototype cycles. You must balance short-term performance upgrades against long-term ownership costs and supplier contracts. Return on investment criteria often determine whether a concept moves from dyno to track.

Supply Chain and Technical Partnerships

You rely on a tight network of specialized suppliers for turbos, MGU-H/MGU-K components, and lightweight castings. Lead times for precision machining and exotic alloys can be months, so you must synchronize procurement with development milestones. Disruptions—capacity limits or single-source dependencies—directly delay homologation and race deployment.

Strategic partnerships shape technological scope; a power unit program often blends in-house design with third-party IP and manufacturing. You need clear contract terms for intellectual property, update cadence, and quality standards. Misaligned expectations between you and partners increase integration risk and can erode on-track performance.

Conclusion

You see how F1 power units combine cutting-edge materials, hybrid systems, and software to deliver peak performance within strict regulations. These engines balance sheer power with energy recovery and efficiency, shaping race outcomes and team strategies.

You should expect ongoing evolution as rules and supplier landscapes shift. Teams invest heavily in integration between ICE, MGU-K, MGU-H, and control electronics to squeeze tenths of a second from lap times.

Your appreciation of F1 engines should include their role beyond speed: they drive engineering innovation that filters into road cars and motorsport technology. The pursuit of efficiency and reliability under race conditions fuels broader advances in lightweight materials and powertrain control.

Key takeaways:

- Hybrid architecture remains central to performance and sustainability.

- Software and electronics increasingly determine usable power and strategy.

- Supplier partnerships and regulation changes directly affect competitive balance.

You will find following seasons reveal incremental gains rather than sudden revolutions. Stay alert to rule changes and new supplier entries; they will influence which teams extract the most from these sophisticated power units.